When car wash systems first hit the market, the only type of car wash available was a friction-style car wash. These were the days when the wash system’s so-called “brushes” featured stiff bristles that rubbed against the vehicle to remove the accumulated dirt and road grime. The brushes were undoubtedly effective at doing their job, but they came with one caveat: the possibility that the contact they made with the vehicle could affect its finish or damage components like antennas, mirrors and door handles.

Fortunately, wash equipment manufacturers have made a lot of improvements since those days.

Today, thanks to advances in wash media, equipment design and performance, and overall operating systems, there are now soft-touch washes that can treat vehicles as gently as a new mother tucking in her baby for the night.

The most obvious improvement in soft-touch wash operation revolves around the wash media. Gone are the days when brushes and, later, soft cloth would “slap” or sweep over the vehicle in an attempt to clean it. The first major advancement in this area was the creation of next-generation brushes constructed of a softer, closed-cell neoprene foam material that is softer and did not allow dirt and grime to cling to it to be passed along to the next vehicle in line.

In conjunction with the now widespread use of closed-cell foam brushes, the manufacturers of soft-touch wash media have worked tirelessly to create a wash wheel that not only delivers the number of touches required to clean the vehicle, but also does it in a quieter, more efficient manner. High wash-wheel RPMs have traditionally been required to optimize cleaning performance, but this new wash-wheel system guides the wash media through the use of precise, deliberate cleaning angles at a lower RPM. While the wash wheel is spinning slower (and quieter), and at rates as low as 30 RPMs, it is delivering a cleaner vehicle because the wash media is in constant contact with the vehicle.

The advancements in the design of the soft-touch wash media and the operation of the wash wheels can result in three major benefits for the soft-touch wash operator:

Higher Throughput Rates

Wash systems that feature advanced soft-touch components are inherently safer and more efficient, with less time required for prepping the vehicle. This results in a wash that does its job in the most time- and cost-effective manner possible, while reducing the chance that vehicle damage or system breakdowns will occur. This is especially important during those busy weekend wash days. Also, wash operators can take advantage of enhanced Cloud-based reporting systems that inform them of how well the system is performing and identify any areas for improvement. All of this information can be retrieved in real-time with a few strokes on a keyboard or through a mobile app. Taken together, higher throughput rates that result in cleaner vehicles will improve customer satisfaction, which will lead to return visits.

Revenue Enhancement

The enhanced cleaning benefits of a soft-touch wash with optimized wash media and wash wheels can be elevated even further through the implementation of one, some or all of the revenue-enhancers that are now available to wash operators. Among the things that can be used to upsell drivers are bug-removal detergents, high-gloss waxes, wheel cleaners and scented soaps. Revenue enhancement can also be gained through the implementation of advanced wash-entry systems that have the ability to interface with a loyalty program. This can be a key component in building repeat business.

Optimized Operating Costs

In conjunction with improved wash media and wash wheels, many next-generation wash systems are using variable frequency drives (VFDs) as a replacement for the old-school hydraulic systems or programmable logic controllers that used to power soft-touch washes. That’s because VFDs are a reliable substitute for hydraulically powered systems that are prone to leaks and breakdowns that result in higher maintenance costs and revenue-robbing downtime. VFDs are also more economical since their energy consumption is based solely on the amount of power that is required to operate the wash system’s various components. The ultimate result is a more robust bottom line for the operator and a satisfied client base that is more likely to show its loyalty to the wash site through return visits.

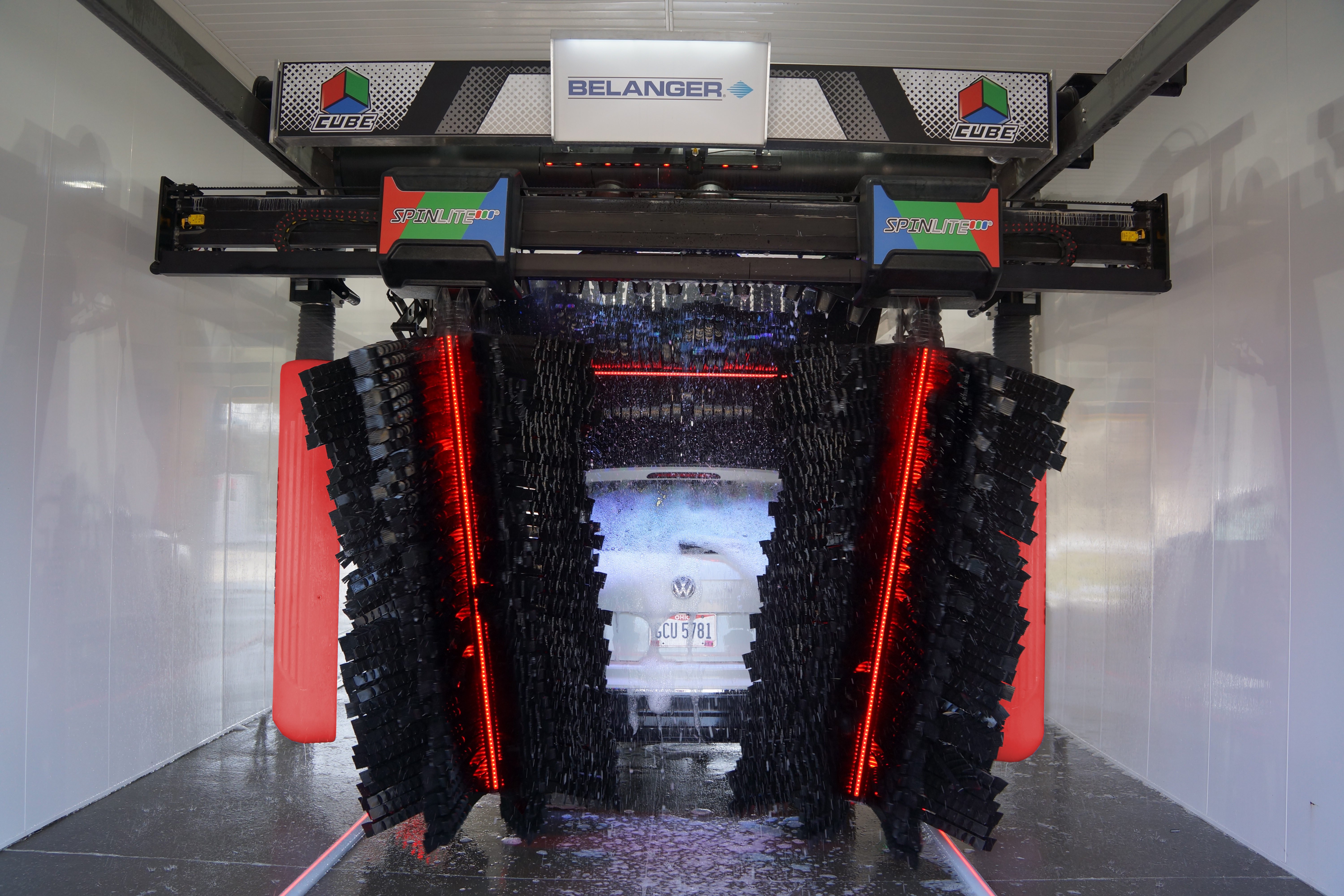

OPW Vehicle Wash Solutions, through its Belanger brand, offers the Cube Wash™ soft-touch vehicle-wash system. The Cube offers a gentle washing experience with more than four times the cleaning touches of traditional soft-touch systems. For more information, please visit opwvws.com.