The manufacturers of pharmaceutical and biopharmaceutical products must confront and overcome three main challenges to “control the controlled environments” within their operations:

To help overcome the main challenges in pharma-biopharma manufacturing, OPW offers the following utility couplings and loading arm systems:

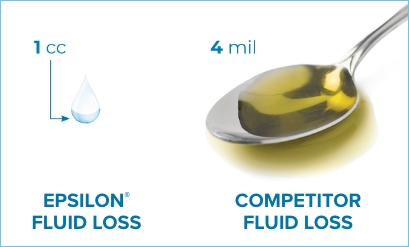

Epsilon buttresses its claim as the industry’s “driest dry disconnect” via a unique double ball-valve design. The design features concave and convex ball-valve halves that nest tightly together. Upon separation, only 1 cc of fluid (equivalent to one-quarter of a teardrop) remains on the nose seal, which can be quickly wiped away. In comparison, dry disconnects that rely on a bayonet-style coupling mechanism can have 4 milliliters (the amount of cough syrup given to a child) or more of residual fluid remain on the nose seal or drip to the floor, necessitating a much more complicated and costly cleanup procedure. The cavity-fill construction of the Epsilon’s internal flow path also helps reduce the possibility of fluid entrapment within the valve body that can lead to microbial contamination, which eliminates another cleanliness concern.

Learn more about our Epsilon Low Spill Coupling System

OPW offers the industry’s most complete line of pre-engineered loading-arm systems for use in bulk fluid-transfer applications, including those that are common in the manufacture of pharmaceutical and biopharmaceutical products. In addition, the following features are specific to OPW loading-arm systems and not offered by any competitor:

For more than 130 years, OPW has been “Defining What’s Next” in creating safe, efficient and reliable solutions designed to solve difficult fluid-handling challenges across a wide range of industries and markets. Today, OPW offers solutions that can overcome a number of fluid-handling challenges, such as helping to prevent safety hazards, simplifying system operation and maintenance, and increasing operational efficiency.

OPW is the only developer of fluid-handling systems that offers a best-in-class combination of local factory support, in-house machining, welding, X-ray, assembly, testing and packaging. OPW is also the only company that is confident and capable enough to offer the OPW Promise: We will not consider the job done until all client expectations are met or exceeded – each and every time.