Water is the enemy of fuel. It can enter tanks in two ways, which are common and difficult to prevent:

1. The spill container during fuel delivery.

2. A bad riser cap gasket or service fitting.

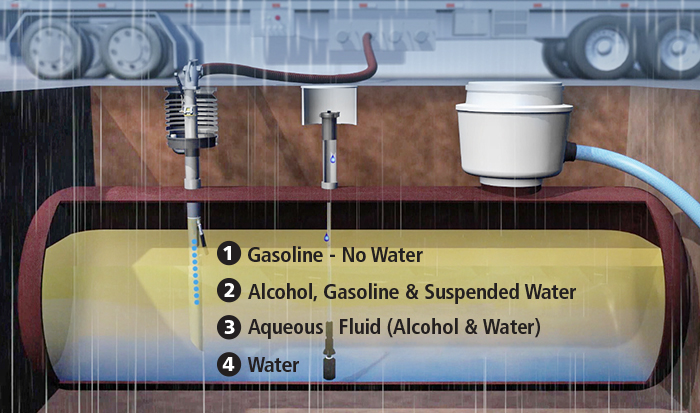

It takes very little water to ruin inventory. In 10,000 gallons of E10, it takes as little as 40 gallons of water to cause phase separation, a condition when the ethanol becomes oversaturated and can no longer be suspended in the gasoline. This can cause four distinct layers of inventory to develop in the tank:

Fuel that has undergone phase separation can lead to:

- A complete loss of tank product

- Costly waste filtration efforts or removal of contaminated product

- Engine damage

For petroleum marketers, engine damage caused by contaminated fuel jeopardizes customer loyalty and results in significant liability costs. For fleet-fueling operations, engines damaged by phase-separated fuel can lead to significant repair logistics and equipment downtime.

OPW's Aqueous Ethanol Float Sensor offers a first line of defense against fuel contamination through industry-leading in-tank detection of unstable water levels and phase separation.